Profit from effective control of raw material and finished product.

From premium ingredients to sustainable manufacturing practices, pet food is increasingly under the eye of pet owners and regulatory bodies alike. As a global and growing industry, pet food is meeting increasing demands from pet owners focusing on sustainability, premiumization health and personalization.

Testing of raw material and material in process is essential to meet expectations while keeping costs under control. Rapid and convenient tests for parameters such as protein, fat, moisture, color and more lead to profitable gains in production efficiency while protecting brand and avoiding customer claims. In particular, the innovative digitalization advantages of today’s analytical solutions ensure the all-important consistency of quality while helping to answer growing demands for transparency and traceability in the production process. With one simple analysis, you can test key parameters like fat, moisture, protein and color and gain valuable insight into your raw material or finished pet food product.

Test it all with rapid NIR technology

Analytical technology such as near infrared (NIR) is ideal for on-the-go tight control of protein and fat while simultaneously monitoring of fiber and other parameters. Near infrared (NIR) analysis and the availability of comprehensive calibrations covering a wide variety of sample types and parameters is particularly useful in helping producers handling the wide variety of ingredients typically used in the pet food production. Formulations can be quite complex with many variables. Having the ability to understand the composition of incoming raw materials allows optimal formulation to meet our nutritional requirements.

NIR analysis and the availability of comprehensive calibrations covering a wide variety of sample types and parameters is particularly useful in helping producers handling the wide variety of ingredients typically used in the pet food production. Formulations can be quite complex with many variables. Having the ability to understand the composition of incoming raw materials allows optimal formulation to meet our nutritional requirements.

Moisture content v. water activity

Dry and wet pet food can provide the same nutritionally balanced diet. The major difference is in the way they are produced and processed, which also affects the difference in the analytical testing needs. Below we will guide you through the different processes and where to benefit from rapid quality analysis.

Wet pet food quality analysis

When looking at wet pet food, it starts with grinding the protein source, or meet ingredients. Hereafter, vitamins, minerals and grains are added. And when the food is mixed, it is cooked and sterilized to be canned.

When looking at the process (see picture above), there are several touch points where rapid analysis is beneficial. First and foremost, the delivery point, where all raw material from meat to grain can with advantage be tested for protein, moisture and fat content. Liquid and dry ingredients can be tested using the FoodScan™ 2, NIRS™ DS3 or NIRS™ DA1650 and meat can be tested with a FoodScan 2 just after the grinder. After the product has been mixed, quality parameters like fat, protein and moisture can be tested using the NIRS DS3, NIRS DA1650 or ProFoss™ 2 and when the product has been canned and sterilized, sample testing of water activity, color and peroxide is of great benefit.

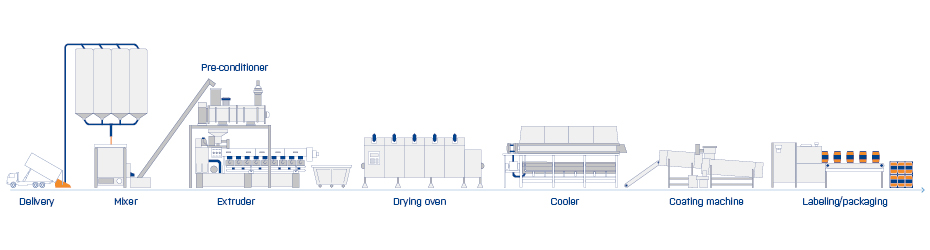

Dry pet food quality analysis

Dry pet food contains many of the same ingredients as wet pet food but instead of adding gravy and canning the product, it is pulverized to create a consistent paste that can be cooked and dried.

When looking at the process (see picture above), there are several touch points, where rapid analysis is beneficial. Again, the delivery point, where all raw material from meat to grain comes in, can with advantage be tested for protein, moisture and fat content. In many cases, Mycotoxin testing is also of great advantage, as you can thereby ensure that no contaminated grain will be mixed in your pet food product.

When mixing the product, and before entering the drying oven, quality parameters like protein, fat and moisture can be tested using a ProFoss 2.

Before entering the coating machine, knowing the fat content is of great value, and in the end, knowing the final product quality allows you to identify and create the exact labeling for packaging. Here you can also test the color using the NIRS DS3.

Learn more about our solutions for the pet food industry