The benefits of continuous in-line process analysis of parameters such as fat and protein are well-proven, but isn’t it complicated and time consuming to get right?

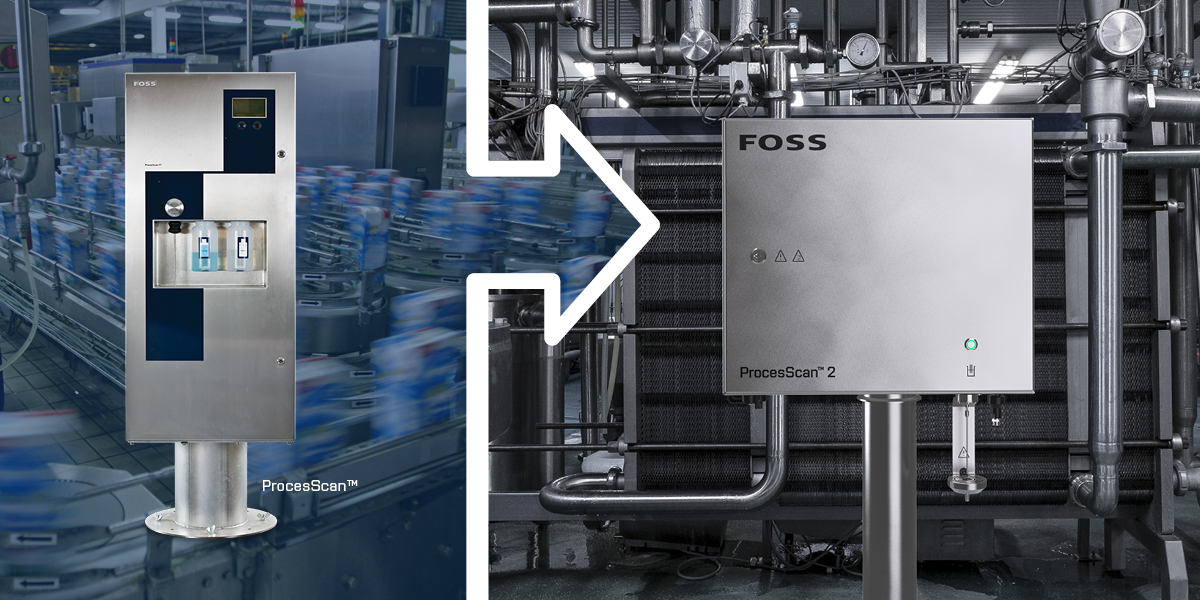

In this video interview, Ryan Nielsen, President of Wapsie Valley Creamery provides a clear answer to this important question by explaining how automation and installation specialists helped to integrate data from a ProcesScan 2 in-line analyzer with the plant’s existing process control systems. “The whole process went pretty smooth,” he says. “We had the machine and system set up a month ahead of time.”

With the continuous analytical data successfully integrated into the PLC sytem, the creamery has improved their milk standardization, leading to improved quality and profit. Ryan says: “The texture and the body of the cheese is more consistent and controllable.” He adds: ”We are putting the right amount of fat in the cheese now and can sell the additional cream that is not needed in the cheese - so that is helping our profitability.”