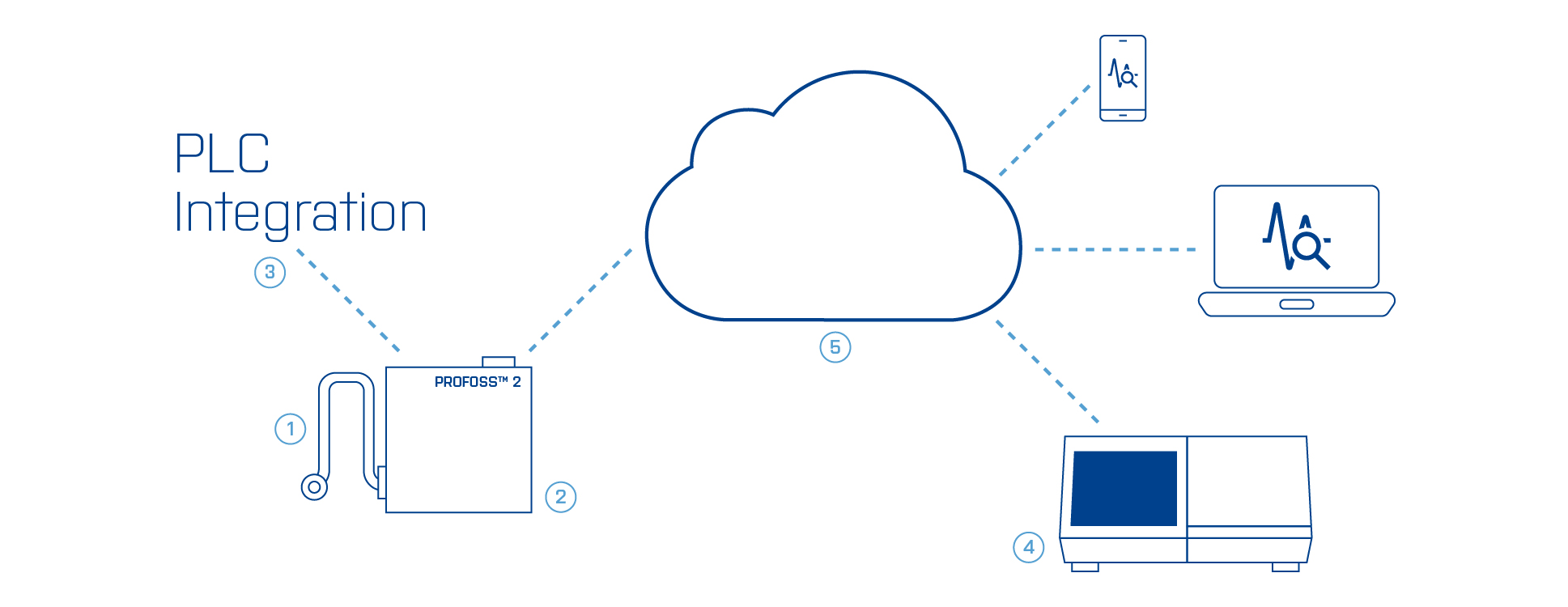

In the above example, a sensor is installed at the outlet of the churn. Variations in moisture (down to 0.02) are monitored through measurements every few seconds. The result data is fed to a PLC system where it is used to automatically control dosing pumps. The process can now react to process changes in real time and variation in moisture is reduced by as much as 50%.

The value of in-line process control

By installing an in-line sensor, dairy producers can get data from key spots in the process every few seconds. This allows closer control of the process according to targets for quality and yield. Adjustments to the process can be made either manually or by using the result data in connection with a PLC system for fully automated real-time control.

The graph opposite visualizes the value of in-line process control. The blue curve shows the original range of variation in moisture. The red curve shows the reduced variation achieved with in-line process control. This allows the production target (blue dotted line) for moisture to be moved closer to the industry specification of 16%. Significant gains in profit can be made with no impact on quality and with no risk of overstepping the 16% threshold.