Five common statements:

-

1. If it is under warranty, I don’t need a maintenance agreement

2. Regular maintenance is only necessary for some technologies

3. I can save on maintenance costs if I have several instruments at the same site

4. Maintenance is only for older instruments

5. It is becoming increasingly common to sign up for maintenance agreements,

so I guess it must be worth it

1. If it is under warranty, I don’t need a maintenance agreement

False: Warranty is quite different from preventative maintenance

Lindsey Nelson, FOSS Customer manager, USA: “Many think that when they first buy a unit, no agreement is necessary for the first year because of the warranty. But a key thing about warranty is that it is not preventative and will not help maintain your instrument, keeping it running just right for reliable results.”

Merete Kræmmer Christiansen, Global manager, Services: “The warranty is important because it protects you from unforeseen costs in case you experience a problem, such as a breakdown, during the warranty period. However, to protect your instrument investment on a longer term basis, preventive maintenance makes a big difference to how long you can expect to have an optimally performing instrument.”

2. Regular maintenance is only necessary for some technologies

False: Regular maintenance adds value for any equipment and new digital services are adding a new dimension.

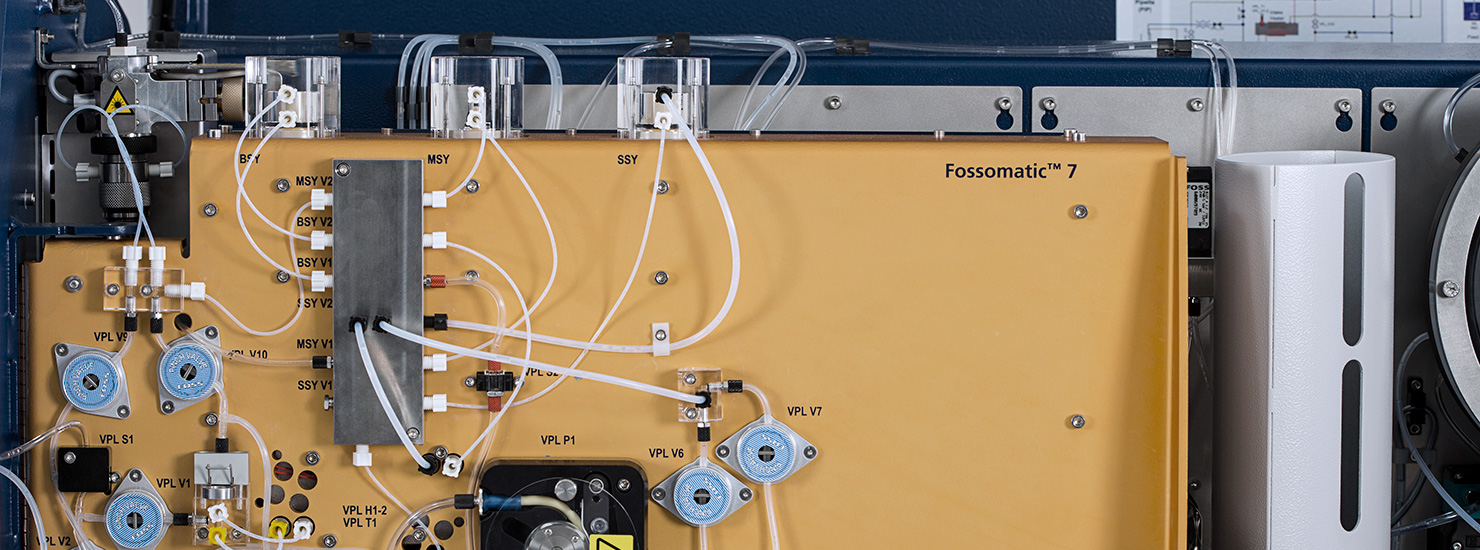

Henrik Jaunet, Senior Customer Support Manager, France: “Flow instruments in particular, such as MilkoScan, WineScan, Fossomatic and BactoScan, need to be maintained regularly in order to stay in good shape and stick to the original specifications. Many wear parts are replaced during a preventative maintenance visit on these instruments. NIR instruments have far less wear parts, but still benefit from regular checks.”

Eric Markwardt, Vice President, Customer and Sales Support at FOSS North America: “There are definitely different needs depending on the instrument. An instrument based on flow cytometry technology like the Bactoscan, needs comprehensive maintenance at regular intervals to continue to perform at high levels.

While the maintenance for an NIR instrument is less intensive, it is still highly relevant. Take the Foodscan for example. The preventative maintenance (PM) protocol should be followed.

For example, this protocol also includes the performance of database cleanup and conducting backups when performing this Preventive Maintenance visit. It’s not uncommon for instrument users to neglect this step and it’s somewhat time consuming, yet essential to do.”

Merete Kræmmer Christiansen: “All instruments require some form of preventive maintenance. Plus, an interesting new dimension for maintaining the overall performance is the advent of so-called digital services. This goes beyond maintaining hardware, for example, with regular validation reports on calibrations for infrared-technology based solutions. Here the new digital services offered by FOSS such as FossAssure can do this remotely and not only once per year but up to 12 times a year.”