Start your journey to improved process control here.

Start your journey to improved process control here.

In today’s dairy industry every drop of milk counts in the quest for efficient production and optimal use of resources. At the same time, ensuring a healthy profit requires nerves of steel to balance increasingly fine margins between success and failure.

While many industrial processes are already closely controlled, artificial intelligence can still find plenty of room for more efficient use of resources. In this video interview, suppliers of a leading AI software platform explain the relevance for dairy processing.

In today’s dairy industry every drop of milk counts in the quest for efficient production and optimal use of resources. As incoming milk accounts for at least 50 % of production costs, this aspect of production is the prime target for improving the outcome of the dairy process.

Automated process control based on key data from the production line is helping to improve efficiency and sustainability across Arla production plants. Process consultant René Klinge Iwang gave us an update on the concept and explains how the reliability of sensors providing the data is a critical factor in any control system

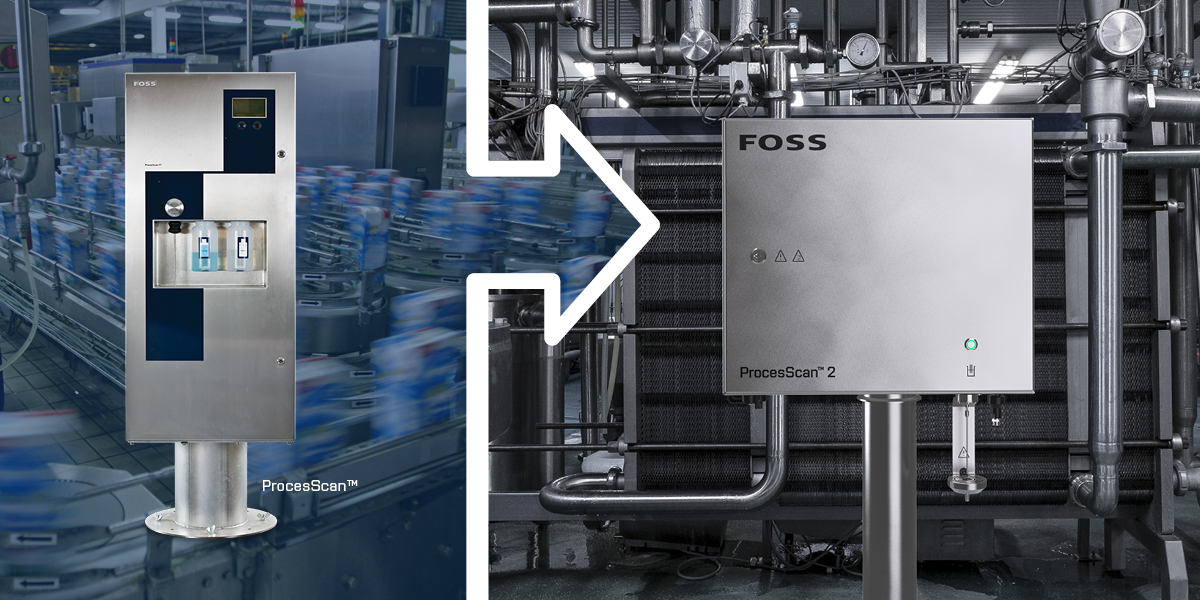

The benefits of process analysis with FTIR technology are well proven, but gains for users have come at a price in terms of running costs and manpower required to keep everything running just right. In this expert Q and A, we explore how a new chapter in the FOSS process analysis story now promises to make process analysis of liquid milk a whole new ball game.

Not only is real-time processes analysis more relevant than ever, advances in technology have also made it faster to implement and easier to run for any Dairy.

A continuous flow of analysis data provided with in-line NIR analysis can significantly increase quality and profit in your butter production. But where in the process should you measure and how? If you are already on a journey towards implementing continuous analysis for optimal control of your butter production or simply curious about the benefits, this resource page will give you an overview of all you need to know.

Real-time process control for improved milk standardization with the next generation ProcesScan™ 2 brings the gold standard MilkoScan™ FT3 technology into the process line. We asked our experts why automated process control is essential in terms of meeting the challenges faced by the dairy industry today.