LIBS is an abbreviation of Laser Induced Breakdown Spectroscopy. It sounds great, but how does it actually work?

In short, the LIBS technology behind the Micral™ solution for element analysis is powered by a high-energy pulse laser that focuses laser pulses onto the sample surface. Each laser pulse is powerful enough to ionize the sample, i.e., breaking it down from solid state, through liquid state, and finally to the plasma state. A UV spectrometer detects the signal strength released by each element in the plasma phase, delivering accurate data about the mineral concentration in the sample.

The process from laser pulse to plasma emission takes about a microsecond and for just one sample measurement, 6000 laser pulses are delivered to the sample.

From plasma to data

The plasma induced by the laser pulse emits radiation where each element in the periodic system has its own unique radiation signature in the shape of emission lines. To the first approximation, the strength of an element emission line is proportional to the concentration of the element in the sample. E.g., a high concentration of calcium in a sample yields strong Ca emission lines, whilst a low concentration of Ca yields weak Ca emission lines. In the Fig. below we show signal vs. wavelength for a grass silage LIBS measurement. A few known element emission lines are highlighted.

The Micral™ LIBS analyzer translates these spectra into applicable data that defines the mineral concentration in each sample using mathematical algorithms.

High accuracy ensured by pressing and searing

Prior to analysis, each sample is pressed into a pellet. Pelletizing improves the quality of the spectra that is produced because the LIBS measurement requires a flat and hard sample surface. If the surface is not flat, it will affect the spectra quality significantly since the measurement is not always in the focus of the laser beam. If the surface is not hard, the explosive force in the laser ablation will induce an uneven sample surface.

After pelletization, the samples are seared. Searing enhances the element emission line strengths, i.e., improving the level of quantification. Additionally, searing reduces the sample matrix effect which improves prediction modelling accuracy.

Precision pulse laser technology

The pulse laser builds up a high level of energy that is released onto the sample through a focusing lens that intensifies the light before hitting the sample. The irradiance at the sample surface, for each laser pulse, is high enough to ionize the sample material, thus creating a plasma. The radiation from the plasma is detected by the spectrometer.

The laser has a repetition rate of 200 pulses per second, and the spectrometer collects sub-scans for 30 seconds. The sub-scans are averaged into one final sample scan – after removal of bad scans.

The LIBS advantage - fast, safe and accurate element analysis

Current testing methods for element analysis are known for being time consuming, requiring many steps, skilled operators, modern lab facilities with fume hoods, use of hazardous chemicals and expensive gases. The Micral™ LIBS solution changes the game by dramatically speeding up test capacity and making LIBS technology accessible to busy labs looking for new ways to improve time to result and scale up element analysis.

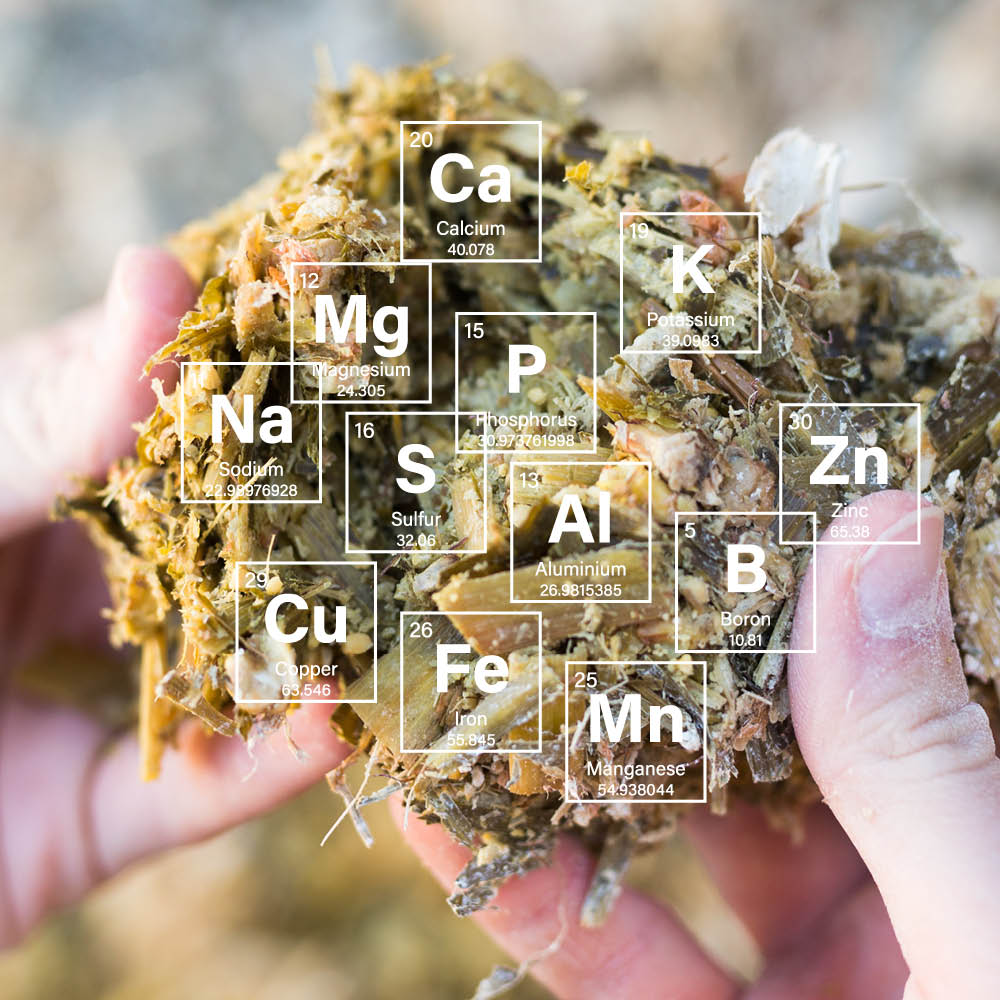

- Valid results for 12 key elements such as calcium, magnesium, phosphorus and more with a time to answer of only three minutes for dried and ground samples.

- Ease of use allows anyone working in the laboratory to make a valid test without the need for special training.

- No chemicals and consumables are required for sample preparation or testing.

- Autosampler included for unattended analysis and even higher throughput.