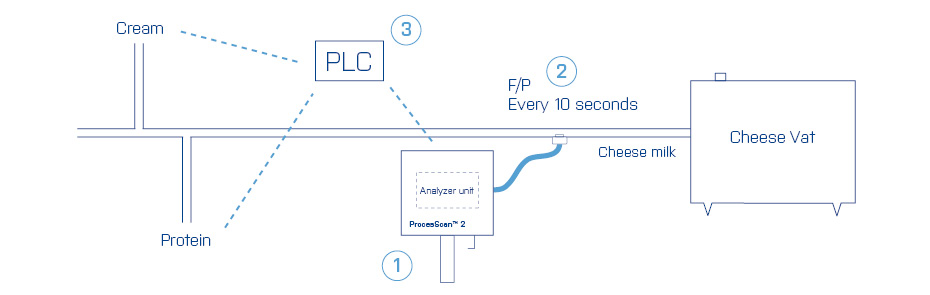

The introduction of the FOSS MilkoScan™ FT120 analyzer in 1992 provided a powerful tool to accurately standardize the F/P ratio in cheese milk. Today, the MilkoScan concept continues in a highly developed form. What’s more, an online solution based on the same technology is now available that can be placed directly in the process. The solution, called ProcesScan™ 2, delivers a result every ten seconds. This enables a high level of control of the F/P ratio and reduction in variation of the fat in dry matter (FDM) in cheese (Fig 1).

With greater predictability in the cheesemaking process, producers are empowered to optimize the use of fat in relation to protein. Producers can manage natural variations in milk composition and improve the cheese making process significantly. As shown in the profit improvement example, this leads to improved business results while maintaining high quality standards.

Fig. 1: Reduced variation in FDM. The blue curve shows the original range of variation and the red curve shows the reduced variation achieved with process control.

This allows the production target (blue dotted line) to be moved closer to the target.

Reduction in variation of FDM and a slight increase in moisture:

- Annual production is 15,000,000 kg cheese and the original FDM is 47.5%

- The deviation from target is reduced by 30% allowing the target to be set at 47.1%

- The corresponding reduction of the FDM will lead to an increased moisture from 37.89% to 37.95%

- Profit is improved by 150,000 Euro per year

Profit improvement example.

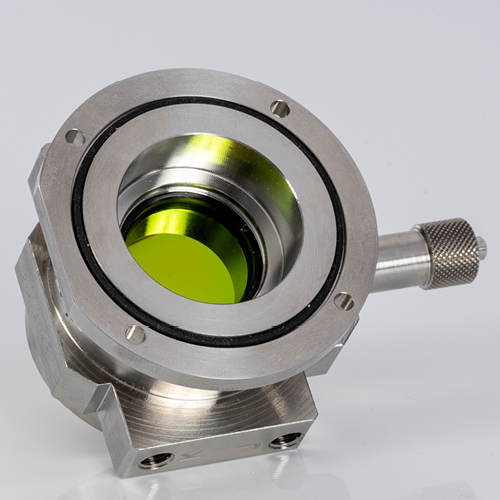

Online sensor improves performance while reducing dependency on skilled staff

The measurements of fat and protein are provided by a sensor (ProcesScan 2) installed in a pipe ahead of the cheese vat. The PLC can now receive results every ten seconds with the same performance as the renowned MilkoScan solution. In addition to improvements in performance, a fully-automated system for standardization of cheese milk helps cheese makers to tackle the growing challenge of finding qualified staff to run the dairy. Instead of making period tests with a desktop analyzer and adjusting the process by hand, the continuous measurements from the process feed the PLC with data to act on automatically.

Another benefit of automation is that operators can constantly monitor and control the fat and protein ratio directly in the flow into cheese vats. This just-in-time approach reduces the need to invest in extra holding tanks and leads to increased capacity.